Food

processing

at its best

We create value for our customers, our community and our investors.

We’re here to do one big thing very well. Our relentless focus on automated food processing solutions makes us single minded and globally present. That’s why Fortifi can visualize and deliver full-lifecycle automation solutions for the entire food industry.

We offer every aspect of the advanced technology necessary to set up a process and automate a plant. But our ultimate resource is our ability to understand what our customers need and to solve their real problems. Whether that requires tools, machines or a complete plant, we’re ready.

Our Purpose

Fortifi automated solutions transform the food processing industry with sustainable operational efficiency. As a leading strategic partner, we further our capabilities through strategic investment and prioritizing an employee and customer-driven culture. We prioritize innovation and safety while we create value for customers, society and investors.

Automated Food Processing Solutions that Enrich the World.

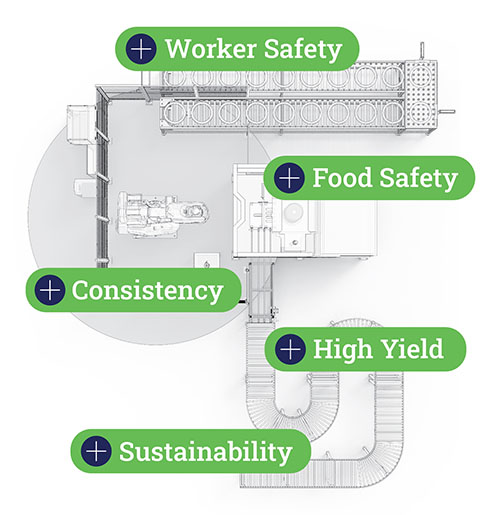

Worker Safety

Automation ensures that processes are carried out consistently, reducing the risk of human error that can lead to safety hazards or contamination. Real-time issue monitoring and less reliance on manual labor for potentially dangerous activities create a safer working environment while they improve productivity.

Consistency

Automated systems offer precise control of parameters such as temperature, pressure, and mixing ratios, ensuring optimal processing conditions that minimize the risk of contamination or spoilage. Automation can also improves product consistency and uniformity, leading to higher quality food products that meet consumer expectations for taste, texture, and appearance.

Sustainability

Automation drives innovation in sustainable food processing technologies, encouraging the development of new methods and equipment that further reduce environmental impact while improving productivity and product quality.

High Yield

Automated systems increase production efficiency, enabling food processors to meet demand while maintaining strict safety and quality standards. Automated equipment is designed for high reliability and uptime, and generates vast amounts of production performance data that can be analyzed to identify opportunities for yield improvement.

Food Safety

Automation offers precise control over processes, reducing the risk of contamination and human error. Automated systems often include tracking and tracing capabilities, allowing producers to monitor the entire production process and quickly identify and address any safety issues or quality concerns.

Benefits of automation

Solve tomorrow’s problems today. Manual processes alone can marginalize productivity and limit versatility. “The way it’s always been done” leaves little room for new products, process innovation and improved efficiency. Now’s the time to reexamine assumptions, break through obstacles and advance the food industry.

Automation makes sense in all types of manufacturing. It speeds up output, eliminates drudgery, and offsets the ebb and flow of the workforce. In food production, optimized environments enhance high-quality yields as well as safety, consistency and sustainability.

The inescapable extremes of complex food production environments make efficiency and safety difficult to achieve – without automation. Fortifi automates every aspect of operational efficiency, profitability and safety. Production efficiency respects the employee as well as the consumer and the bottom line. Automation takes the overwork out of production, and removes workers from tedium and risk at the same time that it speeds up output, eliminates contaminants and helps producers respond to new food trends.

Market segments

Around the world and throughout the food-production industry, Fortifi can help increase efficiency and profitability. Our capabilities extend across all aspects of food production – and rather than try to serve every manufacturing sector, we’re focused on food. Whether that’s meat, poultry, seafood, fruits and vegetables, cheese, dairy, and more, we have the vision to configure complete automation solutions.

*than overall manufacturing

Why Fortifi

We’re solely focused on food solutions, and that’s an advantage other providers can’t offer. We’re a global presence in every aspect of automated food processing solutions. We provide all the pieces and make them work together.

As a full lifecycle solution provider, Fortifi handles food processing automation from a 360° perspective. We identify early-phase needs, design entire plants, provide machines and tools, install and commission lines, provide field service and retrofit existing lines. We’re with our customers at every step of the process and every stop on the line.